|

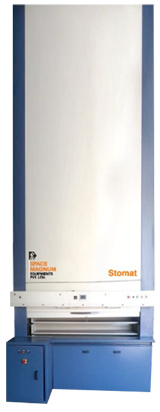

Automated Vertical Carousel

This is as advance storage and retrival system wherein the required material is retrived by just pressing a button on the keyboard.

The concept

In its simplest form, a number of shelves or material storing trays are mounted on Vertical Chain Loops and provided with the PLC Controller. The desired rack can be retrieving, it takes the shortest possible route. The entire system is encased in a sheet metal cladding.

Where to use?

Ideal System for small parts storage where the number of items to be stored is very high.

Benefits

Quick Retrieval

Saves cost, time, energy three times than any conventional system.

Space Saving

The floor space is saved by 40% and the available height is used to its maximum.

Manpower Saving

Precious manpower is saved due to heighest automation.

Low Noise

Electrically controlled and operated by geared chains, so less noise.

Easy to Operate

Maximum operator-friendly system. Electronic sensors stop the system in the possibility of malfunctioning.

Custome-built System

Designed and manufactured taking into account various requirements of different customers. Benefits

Quick Retrieval

Saves cost, time, energy three times than any conventional system.

Space Saving

The floor space is saved by 40% and the available height is used to its maximum.

Manpower Saving

Precious manpower is saved due to heighest automation.

Low Noise

Electrically controlled and operated by geared chains, so less noise.

Easy to Operate

Maximum operator-friendly system. Electronic sensors stop the system in the possibility of malfunctioning.

Custome-built System

Designed and manufactured taking into account various requirements of different customers.

Constructional features

Sofhisticated controller

|

provided with an advanced, microprocessor controller with numeric display |

|

Desired tray, bin or component can be retrieved by its part number |

|

In case of power failure, present position of the carrier is memorised by PLC |

|

Can be interface with a PC or control computer system through RS 232 C serial port |

Safety features

|

Safety bars are provided at the top and bottom side of the operating window. In case of accidental pressing of these bars, the system will automatically stop |

|

The system can be operated manually in case of power failure |

Typical appications ideal for storing

|

Tools |

|

Machined Components |

|

Hardware |

|

Electronic Parts |

|

Components |

|

CDs and Cassettes |

|

Office Files |

|

Medicines |

|

Documents |

|

Small, costly finised goods etc. |

Horizontal Carousel

Triple horizontal carousel for storage of electronic components.

|

|

Multi-loop Horizontal Carousel

For different sizes of metal profiles. |

|

Multi-loop Vertical Carousel

For storage of print cylinders. |

|

|

|

|

|

Technical Data

Stomat Document Vertical Carousel Storage Systems

Vertical Carousels Automated filing system bring all files ro records to a standing or sitting workstation and takes advantage of vertical ceiling height. With the vertical carousel filing and storage system, you have the power to call up the exact record from thousands. Within seconds, it's there, right on your fingertips.

Why have thousands of decision makers chosen Vertical Carousels for their storage and retrieval applications?

|

They save valuable floor space and revolves to bring the media to the user, eliminating or reducing non-essential operator movement: saving time, increasing productivity, reducing misfiles and errors. Using the vertical carousel concept in your office virtually eliminates needless work motions such as walking, stooping, bending, reaching, and searching. No more wasting of valuable employee time and no danger or injuries. The flexible vertical carousel can also be used store almost any type of media, such as letter or legal top and side tab folders, CD-ROM, microfiche, optical disks, checks, cards and more. This flexibility eliminates the need for costly file conversions.

|

|

Automated Vertical Carousels pack the cube from floor to ceiling to provide more density of media in a smaller footprint, they reduce operator travel between storage units and save space! |

All these factors added up to:

|

Faster Retrieval |

|

Incresed Productivity |

|

Less Fatigue |

|

Reduced Errors |

|

Less Employee Turnover |

|

Opprotunities for the phisically Impaired |

|

With Computer Control |

Plain Shelving Type Box Filling System

Technical Data

| |

Unit Widht

2700 / 3050 |

|

Unit Depth

1330 |

|

Filing Capacity |

Cat.

No. |

No. of Carriers |

Average Accesss Time Seconds |

Machine

Height mm |

Minimum

Room Height mm |

Unit Width 2700 mm |

Unit Width 3050 mm |

| For self filing folders max. Folder size 350 mm long x 290 mm high |

| 815 |

8 |

5 |

2210 |

2300 |

240 |

272 |

| 915 |

9 |

6 |

2400 |

2450 |

270 |

306 |

| 1015 |

10 |

7 |

2560 |

2600 |

300 |

340 |

| 115 |

11 |

9 |

2780 |

2850 |

330 |

374 |

| 1215 |

12 |

11 |

2970 |

3050 |

360 |

408 |

| 1315 |

13 |

13 |

3160 |

3220 |

390 |

442 |

| 1415 |

14 |

15 |

3350 |

3410 |

420 |

476 |

| 1515 |

15 |

17 |

3540 |

3600 |

450 |

510 |

| 1615 |

16 |

19 |

3730 |

3800 |

480 |

544 |

| 1715 |

17 |

21 |

3920 |

3970 |

510 |

578 |

| 1815 |

18 |

23 |

4120 |

4200 |

540 |

612 |

| Plain Shelving Type Box Filling System |

|

Lateral or Plain Shelving

Flat Filling System |

|

|

|

Lateral or Plain Shelving Flat Filling System

Technical Data

| |

Unit Widht

2640 / 2998 |

|

Unit Depth

1250 |

|

Filing Capacity |

Cat.

No. |

No. of Carriers |

Average Accesss Time Seconds |

Machine

Height mm |

Minimum

Room Height mm |

Unit Width 2640 mm |

Unit Width 2998 mm |

| For self filing folders max. Folder size 385 mm long x 251 mm high |

| 1211 |

12 |

5 |

2260 |

2300 |

2640 |

3072 |

| 1311 |

13 |

6 |

2400 |

2450 |

2860 |

3320 |

| 1411 |

14 |

7 |

2540 |

2600 |

3080 |

3584 |

| 1511 |

15 |

8 |

2680 |

2850 |

3300 |

3840 |

| 1611 |

16 |

9 |

2820 |

3050 |

3520 |

4096 |

| 1711 |

17 |

10 |

2960 |

3220 |

3740 |

4352 |

| 1811 |

18 |

11 |

3100 |

3410 |

3960 |

4608 |

| 1911 |

19 |

12 |

3240 |

3600 |

4180 |

4864 |

| 2011 |

20 |

13 |

3380 |

3800 |

4400 |

5120 |

| 2111 |

21 |

14 |

3520 |

3970 |

4620 |

5376 |

| 2211 |

22 |

15 |

3660 |

4200 |

4840 |

5632 |

| Accessories - Partition Plate - Rs. 100/- per number |

Standard Specifications

|

Depth of posting board: 300mm |

|

Height from floor to posting board: 850mm |

|

Electrics: Standard 220/250V 110/127 V 50/60Hz

AC supply. Alternative voltages available. |

|